Student blog: Exploring 3D printing with bio ceramics

At TEDI-London, third-year students have the unique opportunity to take on an industry placement, applying their classroom knowledge to real world challenges. This year one of our students, Caelan, explored the innovative field of bio ceramics. Through his project, Caelan is not only advancing his skills but also contributing to work in sustainable manufacturing techniques. Read more about his journey below.

What are you doing for your project?

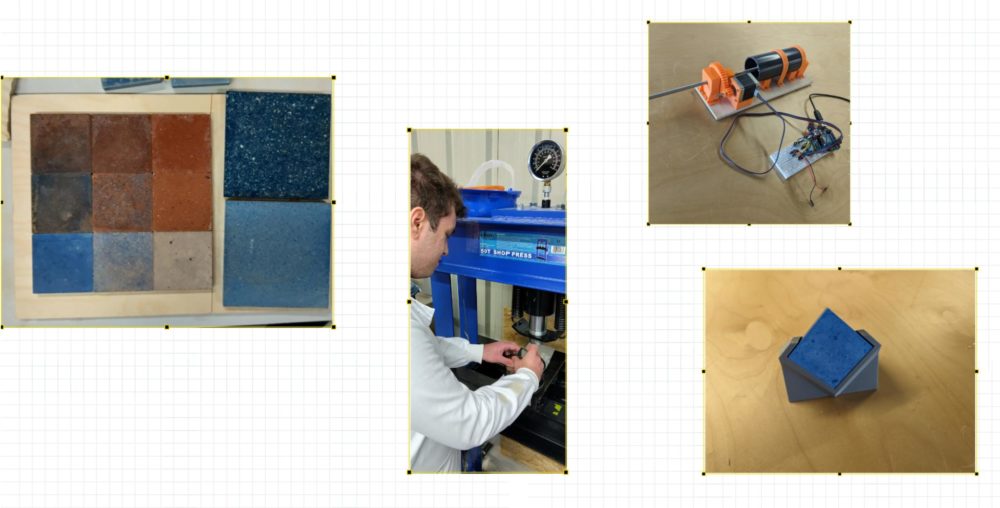

I am exploring the innovative world of bio ceramics and their potential for 3D printing. The company that I am working with, DeakinBio, is a start-up that has made eco-friendly clays that are a blend of waste mineral powders and bio-based binders, offering an eco-friendly alternative to traditional ceramic tile materials.

DeakinBio would like to use their clays commercially, and I am researching whether 3D printing might allow them to do this. As they are a small start-up, the impact of this research could be significant and offer a tangible contribution to their growth and innovation.

Why did you choose this project?

My passion for 3D printing and eco-friendly initiatives drew me to this project. Bio ceramics do not need to be fired in the same way as traditional clay, so production does not release huge amounts of greenhouse gasses. 19 million tonnes of CO2 are released annually in Europe alone from the production of ceramics. DeakinBio’s approach not only slashes these emissions but also offers a more affordable and accessible manufacturing technique, as it currently has a 94% lower carbon footprint than traditional tiles. It’s amazing to be working with a company at the forefront of working to save our planet.

Is it going as you expected?

Aligning with various stakeholders and navigating budget constraints has meant progress has been slower than expected. Whilst challenging, this has been an enlightening learning experience for me and offers a true taste of professional life. Having a plan at the beginning is important, but things don’t always go according to plan!

What would you do if you had more time?

I am working with one ceramic formulation, but the company has several which might all need slightly different techniques to print successfully. Given more time, I’d like to experiment with the different ceramic formulations DeakinBio offers, each likely requiring unique 3D printing techniques: Are they robust or easily breakable, are they heat resistant, resistant to thermal shock and/or chemically stable?

Ceramics are currently used in many diverse areas, from space rockets to tea sets, building construction to human bone replacement. With new methods of production, new use could also be found.

How do you feel TEDI-London has prepared you for this industry placement?

I had not done any 3D printing before coming to TEDI-London. Being able to experiment with the printers on campus and talk to people with more experience has been instrumental. I have also learned how to use SolidWorks, which is a computer aided design (CAD) package. I passed level one in my second year, and I am ready to take level two. This has allowed me to print out the unique components that I need for the build and to design modifications for printing ceramics rather than plastics.

The project-based approach at TEDI-London has sharpened my skills in planning, teamwork, time management and adaptability – all of which are essential for thriving at work.

Any tips for next years’ students undertaking a placement?

Keep a detailed logbook of everything you do. This includes conversations with your mentors and internet sites that you visit. It allows you to remember what you have done when you come to write up the project and allows you to explain your decisions. Also, don’t panic if things don’t go to plan. The way that you handle unexpected events is just as important.

More Student blogs articles

Student blog: a closer look at the right to repair