Guest Blog: Why all waste should be treasured

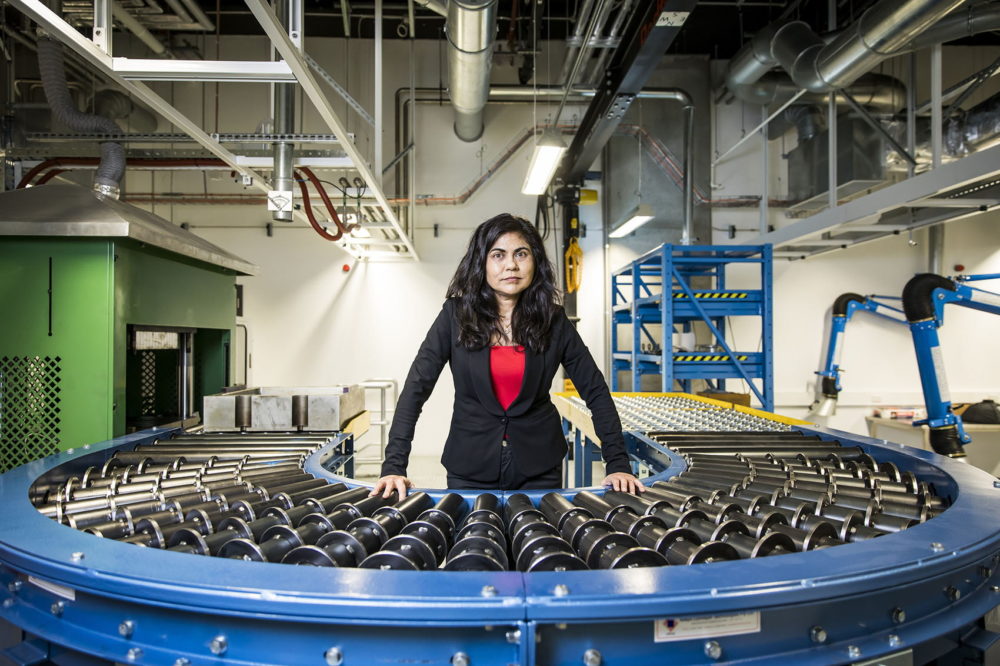

To mark Recycling Week 2020, Professor Veena Sahajwalla, from our partner university UNSW Sydney, explores the relationship between manufacturing and recycling, and how engineering new recycling technologies will be a step forward for sustainability.

Seeing waste as a renewable resource

The year 2020 has brought into sharper focus the main challenges facing global communities and societies.

Not least of those is one of the greatest challenges of the 21st Century – the issue of waste and recycling, as we strive for greater sustainability and reduced environmental impacts for our world.

As COVID started to cause organisations and businesses difficulty in obtaining materials and products for their operations, the notion of ‘sovereign capability’ – where a nation relies more on its own resources and materials – has provided a boost to the sustainability discussion.

Engineering and Science play a central role in this existential challenge. For me, I see a new era in the alignment of recycling and manufacturing as part of the solution to a more sustainable human way of life. Adopting and operationalising circular economies – where materials are kept in use for as long as possible to create greater sustainability – will only occur through such an alignment.

The UNSW SMaRT Centre is helping to create this new alignment, even more important now in the new COVID-19 era, to address the challenges around delivering more sustainable materials and product outcomes.

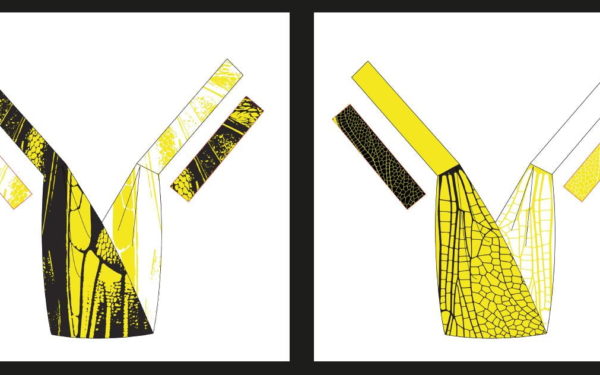

Engineering prototypes from recycled materials – UNSW SMaRT Centre

The SMaRT (Sustainable Materials Research and Technology) Centre at UNSW created the phrase ‘mircorecycling science’ to describe its novel approach to researching innovative approaches and technologies to reform various waste streams into value-added materials and products, through decentralised manufacturing to help local, regional and rural locations.

Ever-increasing population, technological advancement, variable consumption trends and lack of efficiency in using materials, are forcing us near a crisis point in terms of waste management.

Australia’s governments have agreed to ban the exporting of glass, plastic, paper and rubber tyres from January 2021, so we need to start treating these waste items as the ‘renewable resources’ they really area and feed them back into manufacturing and divert them from landfill, stockpiling and incinerators.

A key challenge is that existing, centralised recycling and waste treatment methods at scale often just turn things like PET bottles back into PET bottles. What we need is a recycling and manufacturing system that can innovate to reform waste for more diverse and value-added end uses.

Recyclers traditionally haven’t seen themselves as manufacturers and manufacturers haven’t seen themselves as recyclers, but we need them to.

So, if we accept that we need plastic, for instance, and want to keep it out of landfill and incinerators – which destroy these materials for ever – we need a system that treats it as a renewable material.

The SMaRT Centre, through its microrecycling science and Microfactorie® technologies, can transform waste plastics into feedstock resource for manufacturers and other 3D printing users, with this model of decentralised manufacturing that provides distributed benefits.

One recent example is prototyped frames for face shields for use in medical settings, using filament made from 100% waste plastic using our Microfactorie® technology.

Transforming waste for the future

We now have an incredible opportunity to solve for numerous existential problems at once: we can collectively address waste and recycling issues and lower our carbon footprint, while also enhancing our manufacturing capability, thus creating new supply chains to enhance our sovereign capability.

COVID has unearthed the weaknesses in our current way forward to meet sovereign challenges but we can start a whole new ‘green materials’ movement where we use waste as renewable resources for manufacturing to supercharge our economies which are going into some of their biggest recessions.

This could lay the foundations for the next economic recovery or growth period. We are adding a fourth R to the three Rs of Reduce, Reuse and Recycle, with Reform, by transforming waste into value-added materials. This is a key principal for our new ARC Microrecycling Hub into battery and consumer wastes.

Doing onshore and more sophisticated processing of recycling as part of manufacturing can change the game for Australia, and all countries around the world, particularly given the current waste, recycling and manufacturing challenges.

The goal is to eliminate the word waste from our vernacular because waste will become the renewable resource we know that it is. Engineers will be at the heart of this change.

By Professor Veena Sahajwalla, UNSW SMaRT Centre

More News articles

Q&A with TEDI-London’s Executive Dean