Using Composite Materials in Advanced Engineering for Design

Our MEng students recently took their learning to new heights by exploring the optimisation of light aircraft wing structures using advanced composite materials. Module Lead Dr Matt Thompson explores.

The brief: Optimising aircraft wings

During their Advanced Engineering for Design module, our MEng students explored the optimisation of light aircraft wing structures using composite materials.

This saw them get stuck into the foundational theories behind the solid mechanics of composite materials, manufacturing processes, and performance loading for aircraft wings.

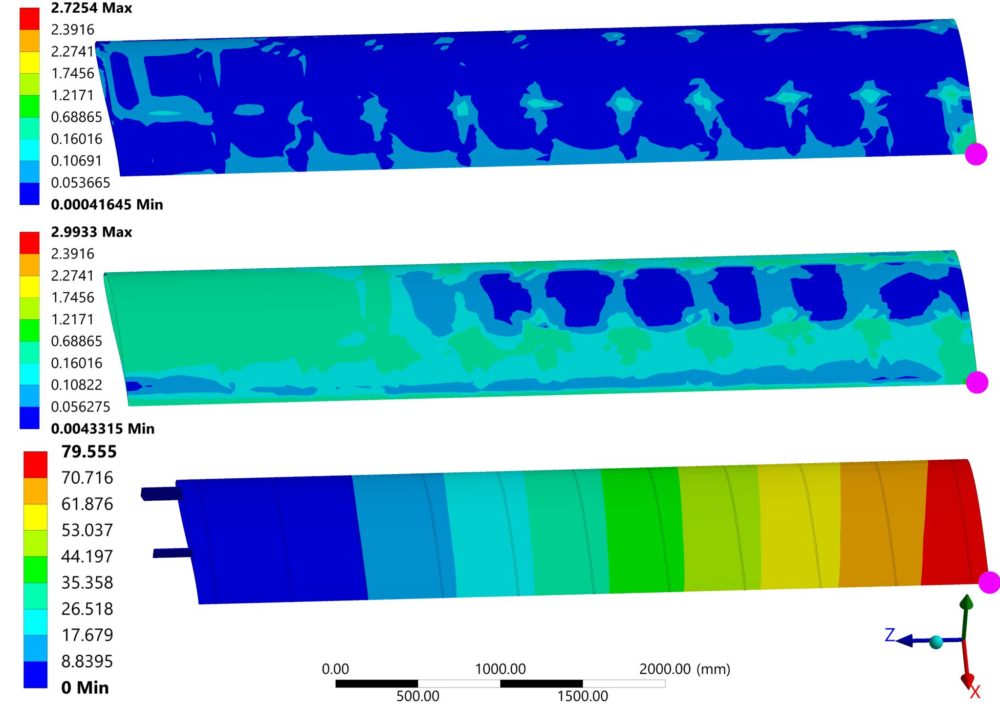

Students were tasked with researching and implementing optimal designs, considering different layups of carbon fibre and glass fibres, as well as exploring various foam core materials in sandwich panels. They then put this into practice by constructing computer models, simulating load conditions, and conducting intricate analyses.

Research in action

A key component of this module is the research aspect, where students attempt to optimise wing structures. Some focused on modelling complex 3D-printed structures to determine their material properties, subsequently utilising these models in finite element analysis to assess performance. For instance, Seb explored the effectiveness of 3D-printed gyroidal shapes—a radical advancement from traditional materials—and investigated their performance implications.

Students used advanced analysis software to simulate complex loading on aircraft wing structures, analysing the stress profile and predicting complex failure behaviour within the material.

They then culminated their research with the composition of a comprehensive conference paper, showcasing their discoveries and contributions to the field.

Advanced Engineering for Design

This module spans both third and fourth years’ at TEDI-London. The former emphasised the modelling of complex behaviours with students analysing wind turbines and airflow dynamics, utilising material mechanics to predict failure within the structure.

The second module in year 4 pushes boundaries further, presenting students with sophisticated composite materials and the intricate mechanics they entail.

The journey from understanding basic material dynamics to pioneering new composite materials shapes them into adept researchers and critical thinkers – an essential toolbox for future engineers.

See more examples of student projects at TEDI-London.

More student projects articles

Reverse engineering: evaluating the design and function of existing products