Student Blog: Wheelchair design project

I’m Stuart, a second-year student here at TEDI-London. I am passionate about helping others and I was recently able to work on a rewarding extracurricular project where I helped to make a young person’s life easier.

I was first introduced to Sophie, a young person with Cerebal Palsy, through Dr Kate Crawford (Senior Teaching Fellow at TEDI-London). Sophie uses a wheelchair to help with her mobility, and her mum talked us through some of the design impracticalities she is currently facing when using the chair, to see if we could help:

The challenge

1– The tray table on the wheelchair is transparent – this results in some problems with identifying objects as Sophie’s condition causes visual impairment.

2– The tray table does not have a lip all the way around – items keep falling off.

3– Sophie’s arms get stuck in the slot where her body sits.

4– It can be inconvenient not having a separate area for ‘messy’ play and ‘computer’ play.

Working with Dr Crawford and Sophie’s mum, we identified the following solutions together. This process of working directly with users is often called ‘co-design’. It means listening and testing out what I could implement to help address these issues and enhance the design:

1– Change the colour of the tray table (multiple ways of doing this)

2– Add extra tabs which cover all the external edges.

3– Customise the slot to fit Sophie better (this was an interesting challenge to find the correct dimensions)

4– Have a second inner tray to provide more versatile usability.

The design process

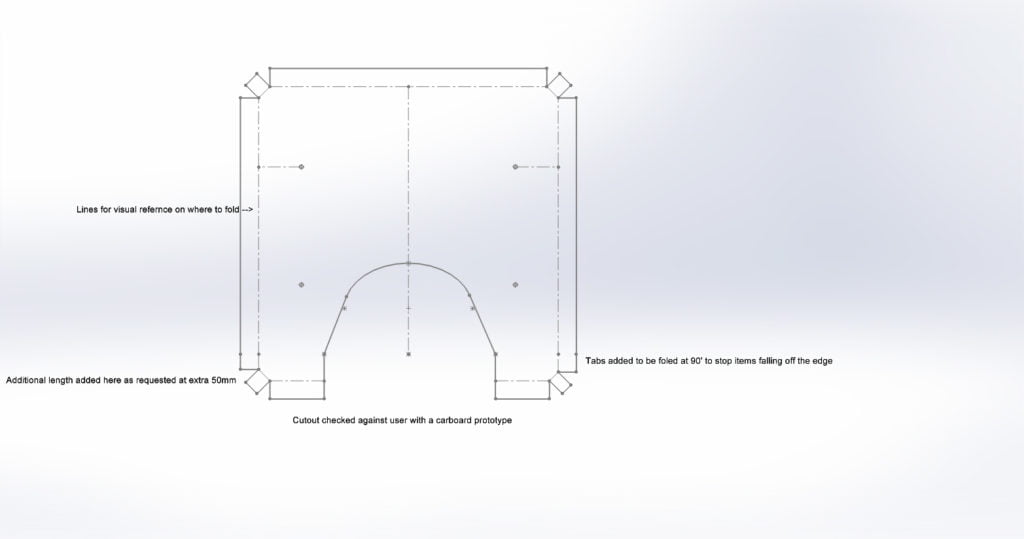

I set out to recreate the tray table on Solidworks (a CAD software used at TEDI-London and widely within companies) as a 2D diagram which could be cut out using the laser cutter we have onsite.

To redesign the tray, I needed to take a few key measurements from the existing table, which included the current overall dimensions, the mounting hole positions as well as the height of the lip. From this, I could sketch out the design.

Next, between myself and Sophie’s mum, we traced the existing cut-out onto cardboard. Then we worked backwards to calculate the new cut-out dimensions (this wasn’t easy since it was more of a trial-and-error process than a fixed measurement).

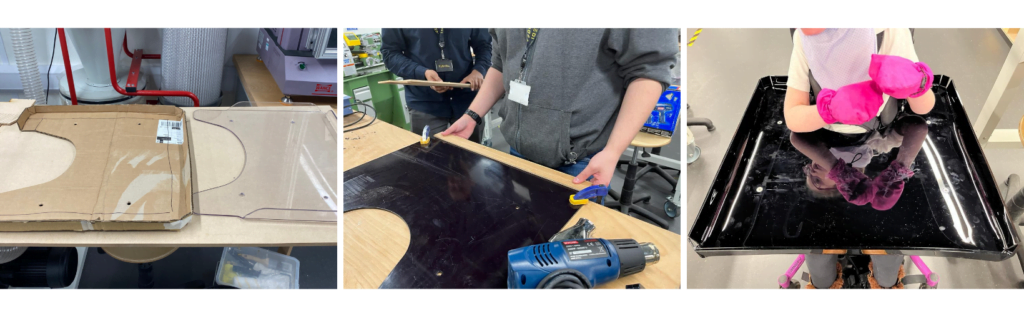

Before making any other adjustments to the design, we did an initial prototype which covered the bottom mounting holes but, most importantly, the cut-out. We then made a few minor adjustments to the dimensions from this prototype.

The second visit led to further discussions around the design and a rethink about how we would use the inserts. The original plan was to have a ‘messy’ insert and a ‘clean/computer’ main tray. However, this would be impractical, so we changed that to a smaller ‘clean/computer’ insert with a ‘messy’ main tray. On a trial basis, we created a temporary insert which Sophie took away with her to see how well that worked with their current setups at home. We also did a mock-build of the tray using recycled cardboard packaging to test my design’s dimensions and extensions against Sophie’s.

The tray table prototype

On their most recent visit, I did the final checks with the cardboard tray table against how Sophie sits, and I sent the final CAD file to the laser cutter. This cut-out fit Sophie very comfortably, and we decided to go forward with the next steps, which included Countersinking (a process in which you drill away some more material so that the head of a screw lies in line with the surface of the material) and finally the bending of the sides.

The bending of the sides was a challenging process since we cannot bend large sheets of plastic on campus; however, after some troubleshooting with the makerspace technicians, we found that a simple heat gun worked on bending the acrylic, although this process takes a lot longer.

To conclude, this prototype was a success. I learned a lot when working through this project, and we have decided that a second version of this prototype will be considered down the line when we can eventually acquire a larger plastic bender.

On a personal level, I found this project both challenging and fulfilling. I got to experience the process of making something bespoke for a user who needed help, and I am so glad I got the opportunity to work on this with Sophie and Victoria. It has always been an aspiration of mine to work in healthcare design; I hope that in the future, I will be able to do more projects like this.

Thank you for reading!

More Student blogs articles

Student Blog: Civil Engineering of Great Zimbabwe