Summer school students showcase solutions to tackle plastic waste

Last week marked the end of our 2024 summer school, centred on the pressing global issue of plastic waste and how we can better reduce and repurpose single-use products. 6 student teams undertook a 3 week design print, collaborating with industry experts across redesign, material science and waste management, to develop innovative solutions to this challenge.

Their time at TEDI-London concluded with a showcase day, allowing each team to present their environmentally focused prototypes and concepts to an audience of peers, industry partners, local community members and TEDI-London staff. Here’s a look at the ideas they came up with:

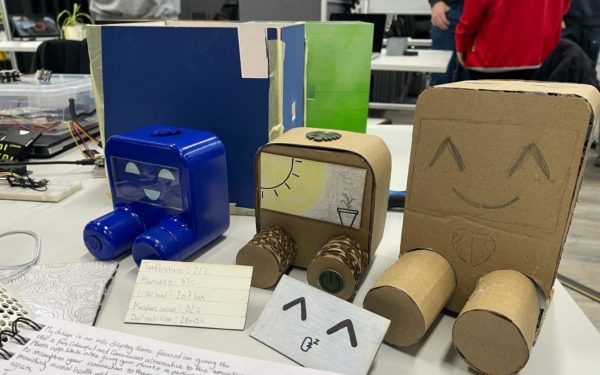

BinLytics Connect

Awarded the industry prize at the showcase day, this team developed a smart bin that improves recycling processes within office environments. The system tracks waste disposal habits and provides users with detailed, gamified feedback to promote effective recycling practices. This project not only addresses the disposal of office waste but also educates users on the impact of their actions, fostering a culture of responsibility and sustainability. The team suggested that this technology can be used in other environments, such as schools and public spaces.

Polyfloss Renewable

This team focused on the significant waste management challenges in Bangladesh, which produces over 800,000 tons of plastic annually. Their solution, Polyfloss Renewable, is a low-cost, sustainable fibre made from recycled PET plastics, designed to empower local weavers and support cottage industries, allowing them to produce culturally significant mats at a fraction of the traditional cost. By transforming waste into useful products like the mats, this project aims to enhance economic independence and environmental sustainability in low-income communities.

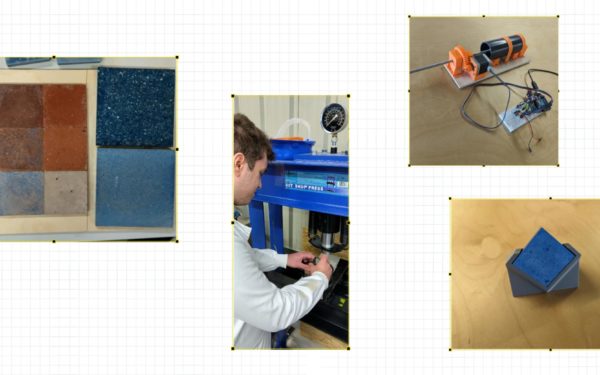

Spark Cycle

Spark Cycle addressed the environmental challenge of disposable vapes, which are often discarded improperly, leading to significant waste. Each week, millions of vapes are bought and a large portion of these end up contributing to environmental pollution. The Spark Cycle team developed an innovative recycling solution that transforms used vape devices into functional electronic gadgets, such as fans and power banks. This process not only repurposes the lithium-ion batteries and plastic casings found in vapes but also promotes a circular economy.

Their initiative includes a robust behavioural change campaign aimed at young adults, particularly those frequenting music festivals and other public events where vape use is high.

Re:Sort

Re:Sort is meant to tackle the challenge of sorting various types of plastic waste, which is essential for effective recycling. Their smart bin system features an advanced scanner that uses discrete near-infrared (NIR) spectroscopy to identify different plastics based on their unique reflective signatures. Upon identification, the bin automatically opens the appropriate compartment for each type of plastic, ensuring accurate sorting and reducing contamination.

Designed for user-friendliness, these bins can be integrated into various settings like offices and public spaces. Re:Sort would collaborate with recycling companies to ensure that sorted plastics are processed correctly, supporting the broader goals of reducing virgin plastic use and promoting a circular economy.

Eco-Sip

This project addressed the environmental issue of non-recyclable coffee cups by introducing an innovative cup design with a removable seaweed-based plastic lining. This feature would allow consumers to easily separate the biodegradable paper cup from the heat-resistant lining after use, facilitating better recycling and composting practices.

The design ensured that the paper component can be recycled with regular paper waste, while the seaweed-based lining can be composted, significantly reducing the environmental impact associated with disposable cups. Eco-Sip’s initiative not only offers a practical solution to waste reduction but also sets a new standard for sustainability in the beverage industry.

DissolvaPak

This team developed a solution to combat the issue of single-use plastic in food packaging. Their product is a flexible, biodegradable and water-soluble packaging material designed to completely dissolve within 30 days after disposal. This approach offers a practical alternative that consumers could conveniently dispose of via household sinks or toilets, ensuring a reduction in landfill waste.

Targeting the food industry, DissolvaPak’s goal is to replace traditional plastic packaging used for items like coffee sachets and toiletry miniatures. The material’s safety and compliance with FDA and EFSA standards make it a viable option for widespread adoption, aiming to transform packaging practices in the fast-moving consumer goods sector.

View this post on Instagram

The showcase concluded with industry judges Damon Bonser from the British Design Fund, Emma Collings from British Land and Dr Peter Kay from TEDI-London who awarded the Engineers in Business prize to BinLytics Connect, DissolvaPak and Polyfloss Renewable – a big well done to all teams!

Interested in tackling real-world, practical projects like this one? Apply to study at TEDI-London

More student projects articles

User-centred designs to support plant and planet health