Iterate fast: Unpacking the prototyping process in engineering

Dr. Sam Fishlock, Associate Professor at TEDI-London, explores the first-year Prototyping module at TEDI-London – where students navigate the fascinating process of transforming early ideas into tangible models.

Prototyping is a key design concept, where engineers generate designs and ideas, build them, share and test them, and then reflect and improve.

This process, of rapidly iterating and improving ideas is a proven method of developing innovative products and services to suit users’ needs.

Why are prototypes important for engineers?

Prototyping is a crucial part of the engineering design process, and is where we start to put ideas into action. This is generally an iterative process – where quick prototypes are initially made and refined over time.

A key aspect of a good prototype is having a clear purpose for its creation. I refer to it as ‘answering the key question’, where there should initially be an unknown aspect about the product’s direction, which the prototype helps to clarify. The questions could range from ‘How do these parts really fit together?’ to ‘How is this product really going to feel in my hand?’, or more technical queries like ‘Is the algorithm for this robot working well?’

A prototype is also a good communication tool. It can help you to demonstrate to your colleagues or to a user what the product is going to look like or how it will function. You can then use that feedback to improve the product for the next iteration. There is a Silicon-Valley type saying which is ‘fail fast’ but I prefer ‘iterate fast’.

What were students challenged to do in their Prototyping module?

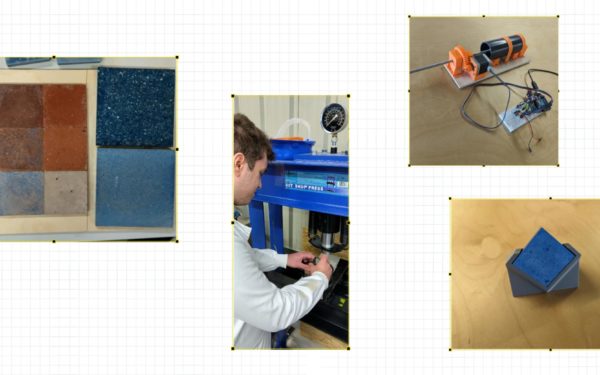

In this years’ module, students were given an overriding theme to redevelop a product so that it could be easily repaired, aligning with the Right to Repair movement.

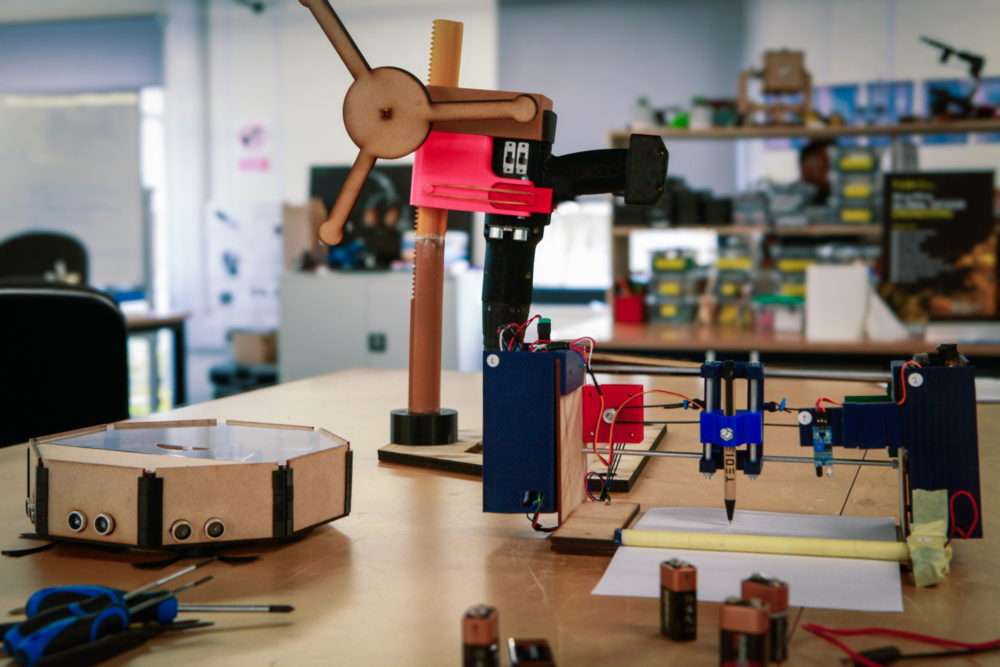

They had a choice of three different products: a robotic vacuum cleaner, a 2D pen plotter, and a modular drill system that could be used either as a hand drill or as a pillar drill.

Students used components nearly entirely from ‘for repair’ (i.e., listed as broken) from eBay. Some of the results were really impressive!

Did students collaborate with any industry experts during this project?

We had a visit from Danielle Purkiss of the Big Repair Project. This is a research project looking at the Right to Repair movement. We had a great discussion where students were able to ask questions on the movement overall, including how government policy, public perception, and even the taxation system, links together to create an environment that either promotes or slows down a repair economy. This was really helpful to see where our work as engineering designers comes together.

What engineering disciplines and skills did the prototyping module cover?

Students engaged in mechanical and some electromechanical engineering, along with product-design.

They developed a whole host of skills during the module including:

• Translating user requirements

• Sketching and lo-fi prototype making including using cardboard

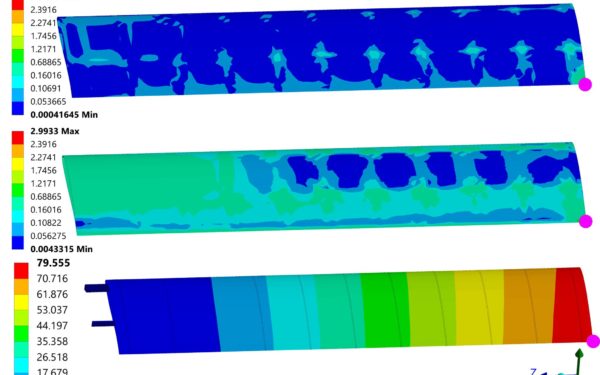

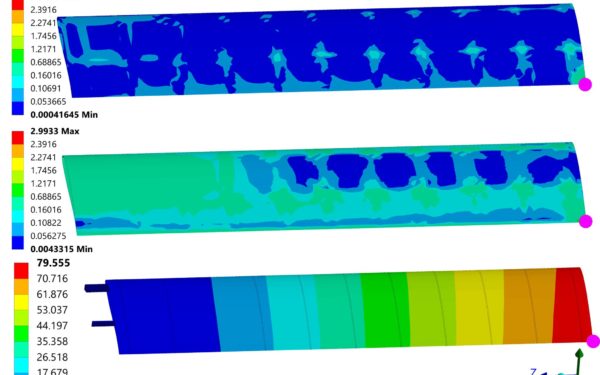

• 3D CAD using SolidWorks

• Virtual prototyping (for example using the Arduino emulator on Tinkercad)

• Implementing a microcontroller system using Arduino sensors and actuators

Read more about the types of topics you’ll learn as a Global Design Engineer.

More student projects articles

Student blog: Exploring 3D printing with bio ceramics